A fermentation mode is a method of cell expansion based on controlling whether there is any inlet flow (feeding nutrients and media into the broth) or outlet flow (removing cell broth).

There are 3 main fermentation modes in upstream processing:

- Batch

- Semi-Batch/Fed-Batch

- Continuous

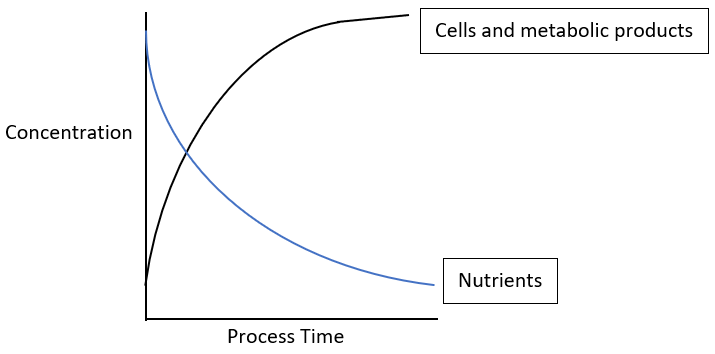

Batch fermentation

In a batch culture, after inoculation of the cells + media there is no addition or removal of broth components until the end of fermentation. In other words, there is no inlet or outlet flow during fermentation. The only exchange during the process is gas exchange, buffer addition and anti-foam if necessary.Therefore, initially the amount of cells will increase rapidly due to the surplus of nutrients, but as time goes on and the cells consume the nutrients, cell growth decreases as lack of nutrition because the rate limiting step.

Pros:

- Flexible schedules: a batch process will have a shorter fermentation time, allowing more flexibility in selecting appropriate times (i.e. having a batch finish on Monday so that no staff need to go in on the weekend). This also allows for maintenance of the vessel to be scheduled easily.

- Versatile: As fermentation time is short, it is easy to switch to a different cell process (i.e. switching from producing antibodies from white blood cells to insulin from human pancreatic cells)

- Low contamination risk: As fermentation time is short, the cells undergo less population doublings as other modes, plus as batch processes are fast there is less time for contamination to occur before cleaning and sterilisation.

- Complete conversion of substrate to product: As no extra nutrients are added and no cells removed until the end of the process there is complete conversion of the substrate / consumption of all nutrients, maximising conversion rate.

Cons:

- High labour cost: Unlike continuous, it is not possible to automate batch processes for a long period of time since the reactor will need to be set up for the next process after one finishes. This means more staff need to be on site = more cost.

- Lots of idle time: Reactors in batch mode need to be unloaded, cleaned and sterilised before and after every batch, during which times reactor will not be making any product. This reduces profits.

Semi-Batch/Fed-batch

In a semi/fed-batch fermentation either the inlet or outlet pipe will be open, but not both i.e if feed is being fed into the reactor, nothing will exit the vessel and vice versa. Since it’s much more beneficial to add feed than remove cells, this is usually run as a fed-batch. A fed-batch operation is when the process starts off as a batch process but after a certain point media (containing nutrients) is fed into the vessel incrementally. This causes the volume of the broth to increase.

Pros:

- Controlled conditions: cell concentration can be manipulated by the addition or non-addition of feed.

- High cell densities: Achievable because feed is added whilst no cells are removed.

- Low contamination risk: Same as batch

- Flexible schedule: Same as batch

- Versatile: Same as batch

Cons:

- Downstream processing will need to be able to cope with higher cell densities if fed-batch is used.

- High labour cost: Same as batch

- Idle time: Same as batch, but less pronounced as higher cell densities are achieved, which means more product.

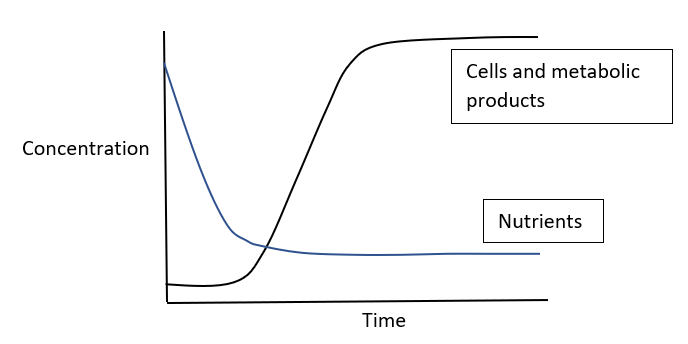

Continuous Fermentation

In continuous fermentation, both inlet and outlet pipes are open, allowing feed to enter and cell broth to leave. The inlet and outlet pipe have the same flow rate, meaning per minute the amount of feed entering the vessel is the same as the amount of cell broth leaving the vessel. This means that the volume of the reactor remains constant.

Pros:

- High productivity: Reactor is constantly churning out product since it is continuous – less idle time.

- High efficiency of capacity: The process is efficient as product is constantly being produced.

- Easy automation: Reactor is run on the same settings for a long period of time.

- Constant product quality: Since the concentrations of cells and feed are constant and all the product is from the same batch, product quality tends to stay constant.

Cons:

- Contamination: As process time increases so does the likelihood of contamination.

- Inflexible: Maintenance needs to be arranged before process begins since fermentation can possibly go on for months. Also, you will need to commit to producing one product since it is a long term process.

- Mutations: As this is a long term process, there will be many more population doublings, which increases the likelihood of mutations arising.

- Downstream processing will need to be adjusted to also work continuously.

If you have any questions, please leave a comment below and we will answer it to the best of our ability!